- FOR TA 10 & TA14

- Feed/discharge conveyor belts

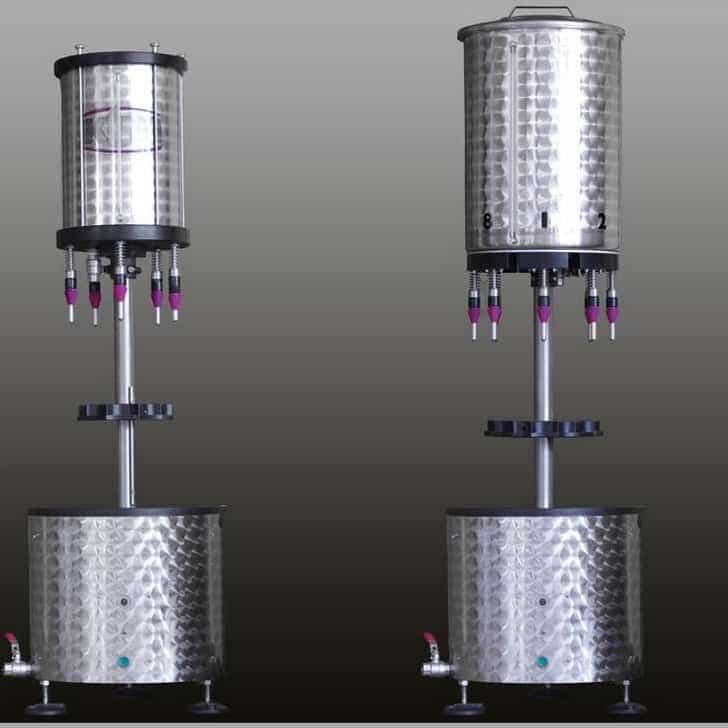

- Electric fill level monitor

- Station for superimposing CO2 and fill height levelling after the filling process

- Mobile stand

- Add-on kit for filling bottles with hot liquids (digital temperature gauge, etc.)

- Bottle pre-evacuation with inert gas injection (fully automatic variant required)

- Sterile filter cartridge for tank ventilation